SGO solid lubricant performance test (R&D)

SGO

view : 1733

Hello, this is SGO . :)

The solid lubricant applied to the embedded oilless bearing is produced through a pressurization and molding process by mixing lubricating components such as graphite, sulfide, and phosphide, and resins to form internal pores. SGO also produces 100% of these lubricants, and R&D is also actively progressing to improve the stability of lubrication performance, as in the comparison test of other companies' solid lubricants in the last posting .

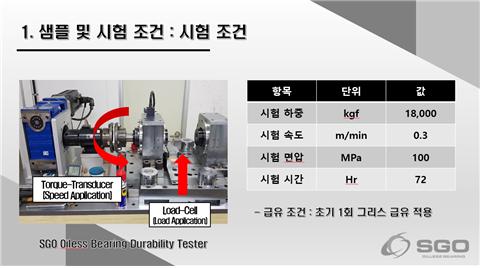

Today, we are revealing some of the results of a solid lubricant performance test conducted by SGO Labs! :D

Solid lubricants are based on components such as graphite, sulfide, and phosphide with excellent lubricating performance, and a molding technology that improves the structure to form pores inside is the key. The internal pores hold the lubricant and release it during use, forming a stable lubricant film . To prove this, one of the two samples with the same specifications was impregnated with lubricant and the other was made without impregnation.

In order to compare the exact performance, it was dry-machined with a general-purpose lathe to remove the effect of the coolant used in MCT and CNC, and each of them was weighed.

As you can see in the picture, the difference in weight between the sample impregnated with lubricant (No. 1) and the sample not impregnated (No. 2) is only 2 g . What happened to the durability test of oilless bearings directly tested by SGO laboratories? Check out the difference that 2g makes below.

First, if you look at the friction surface of Sample 2 , you can see that the surface is rough and irregular irregularities compared to Sample 1 even when you see it with the naked eye. The wear amount measured using the gauge is also very severely worn compared to sample 1 for both the bearing and the shaft, so it is judged that there is little lubrication effect.

In addition, the testing machine owned by SGO Lab is set to stop when the friction coefficient reaches 0.25 . Sample No. 2 had to stop the test because the coefficient of friction was exceeded around 40 hours out of the total test time of 72 hours.

This difference is related to the wettability of the solid lubricant's internal pores and tissue geometry . Wetting is the ability of a liquid such as lubricant to maintain contact with the surface of a solid, which is a lubricant, and is a phenomenon caused by interactions between molecules. When the adhesion and cohesion between the lubricant and the lubricant are balanced, the lubricant holds the lubricant stably.

In fact, if you immerse the carbon lubricant in the lubricant, you can observe the capillary phenomenon in which air bubbles escape from the internal pores in the lubricant . Although the weight difference is only 2 grams, it can be seen that solid lubricants and lubricants play a big role in bearing life and mechanical safety.

SGO is always working to make better products. If you have any questions, please feel free to contact us. :)