Frictional heat Q generated per unit time and unit area is indicated as below.

Q = μ·P·V/J (kcal/min)

J : Frictional heat per unit motion(≒427kgf-m/kcal)

μ : Frictional coefficient

P : Contact pressure (kgf/cm2)

V : Velocity (m/min)

Frictional heat is mainly affected by speed rather than contact pressure. Therefore, for simillar PV values, additional lubrication should be considered for a higher velocity application to prevent seizure to the bearing or the mating shaft.

| Type | Shaft material | Hardness | Shaft roughness |

|---|---|---|---|

| General purpose | General structural steel wiht SM35C or above | Higher strength material is recommended, when foreign substance flows in Rockwell "C" 35 or above |

3~12μ |

| High temperature | Stainless steel or chrome plating | ||

| Corrosive environment | Chrome plating |

- Reduce the shaft dimension to account for the heat expansion amount of the material when it is used on high temperature 100˚C or above.

Heat expansion amount = shaft heat expansion coefficient (α) x shaft diameter (d) x (ambient temperature-room temperature)

Ex) #500SP α : 2.2 x 10-5/˚C - 2 ~ 3 chrome plating is ideal for seawater and liquid medicine.

- Nitrification on shaft is effective in high pressure and low speed application.

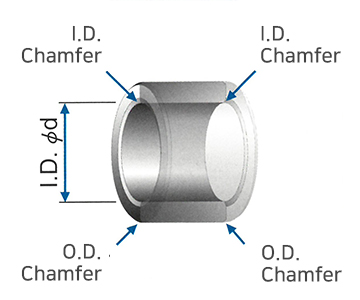

It is ideal to chamfer the both ends of the oil-less bearing in order to prevent stress concentration.

| ID | Chamfer |

|---|---|

| 80or below | 0.5C |

| 80 ~ 200 | 1.0C |

| 200~ 300 | 1.5C |

| 300or below | 2.0C |

Thickness of standard bearing is calculated using the formula below.